Gỗ công nghiệp đang được ứng dụng rất nhiều trong các đồ nội thất hiện nay, vậy gỗ công nghiệp là gì? Có những loại gỗ công nghiệp nào? Và bề mặt gỗ nào đang thịnh hành nhất ngày nay. Các bạn hãy cùng MOIVAONHATOI tìm hiểu ngay trong bài viết này nhé!

GỖ CÔNG NGHIỆP LÀ GÌ?

Thuật ngữ “gỗ công nghiệp” dùng để phân biệt với loại “gỗ tự nhiên” – là loại gỗ lấy từ thân cây gỗ. Còn gỗ công nghiệp là loại gỗ sử dụng keo hay hóa chất kết hợp với gỗ vụ để làm ra tấm gỗ.

Gỗ công nghiệp có tên quốc tế là Wood – Based Panel. Gỗ công nghiệp đa số được làm từ các nguyên liệu thừa, nguyên liệu tận dụng, tái sinh, ngọn cành của cây gỗ tự nhiên.

Các sản phẩm nội thất gỗ công nghiệp hiện nay thường có 2 thành phần cơ bản, đó là: cốt gỗ công nghiệp và lớp bề mặt. Để hiểu rõ hơn về các thành phần này, mời bạn theo dõi các phần tiếp theo.

CÁC LOẠI GỖ CÔNG NGHIỆP PHỔ BIẾN LÀ GÌ?

LÕI GỖ CÔNG NGHIỆP MDF LÀ GÌ?

Gỗ MDF là chữ viết tắt của từ Medium Density Fiberboard. Đây là loại cốt gỗ được tạo thành từ các cành cây, nhánh cây sau đó được đưa vào máy nghiền nát thành bột và trộn với keo đặc chủng để ép ra thành các tấm ván với các độ dày khác nhau như 3ly, 6ly, 9ly, 12ly, 15ly, 18ly, 25ly. Kích thước tấm ván: 1220mm x 2440mm.

Bạn có thể nhìn thấy sự khác biệt hoàn toàn giữa ván dăm và ván mịn. Đúng như tên gọi, ván mịn nhìn bằng mắt thường đều thấy được sự nhẵn nhụi, bằng phẳng của bề mặt cốt gỗ. Với công nghệ phức tạp hơn, nên MDF có giá trị cao hơn so với ván dăm. Đây là nguyên liệu chủ yếu tạo thành nguyên liệu phục vụ tạo ra các sản phẩm nội thất văn phòng : bàn văn phòng cao cấp, tủ tài liệu văn phòng, hộc di động…

Xem thêm: Thiết kế nội thất chung cư northern diamond 110m2 190 triệu

LÕI GỖ CÔNG NGHIỆP HDF LÀ GÌ?

Tấm gỗ HDF hay còn gọi là tấm ván ép HDF là từ viết tắt của từ High Density Fiberboard.

Quy trình tạo nên gỗ HDF diễn ra như sau: Nguyên liệu bột gỗ được lấy từ nguyên liệu sản xuất sản phẩm nội thất là gỗ tự nhiên rừng trồng nguyên khối, luộc và sấy khô trong môi trường nhiệt độ cao, từ 1000 C – 2000C. Gỗ được xử lý hết nhựa và sấy khô hết nước, với dây chuyền xử lý hiện đại và công nghiệp hoá hoàn toàn. Gỗ được đảm bảo chất lượng cao và thời gian xử lý nhanh. Bột gỗ được xử lý kết hợp với các chất phụ gia làm tăng độ cứng của gỗ, chống mối mọt, sau đó được ép dưới áp suất cao (850-870 kg/cm2) và được định hình thành tấm gỗ HDF có kích thước 2.000mm x 2.400mm, có độ dày từ 6mm – 24mm tùy theo yêu cầu.

LÕI GỖ CÔNG NGHIỆP MFC LÀ GÌ?

Gỗ MFC là loại cốt gỗ được tạo thành từ các cành cây, nhánh cây hoặc thân cây gỗ rừng trồng (bạch đàn, keo, cao su…), có độ bền cơ lý cao, kích thước bề mặt rộng, phong phú về chủng loại. Sau đó được đưa vào máy nghiền nát thành dăm và trộn với keo đặc chủng để ép ra thành các tấm ván với các độ dày khác nhau như 9ly, 12ly, 15ly, 18ly, 25ly, cốt gỗ ván dăm có nhiều loại như cốt trắng, cốt xanh chịu ẩm, cốt đen… Kích thước tấm ván theo quy chuẩn: 1220mm x 2440mm.

Cốt ván dăm có đặc điểm là không mịn, nhìn bằng mắt thường bạn cũng có thể dễ dàng phân biệt các dăm gỗ. Đa phần các sản phẩm như bàn làm việc, tủ đều sử dụng loại cốt này.

LÕI GỖ CÔNG NGHIỆP DÁN LÀ GÌ?

Là loại gỗ được làm ra từ gỗ tự nhiên được lạng mỏng ra thành từng tấm có dỗ dày 1mm rồi mang các lớp gỗ đó đi ép chúng một cánh đan xen lại với nhau cùng với chất kết dính. Ưu điểm của gỗ dán là không bị nứt trong điều kiện thông thường, không bị mối mọt co ngót trong thời tiết ẩm ướt.

Điều kỳ lạ là chúng chỉ có 3 lớp, 5 lớp, 7, thậm chí 11 lớp. Lý giải cho điều này như sau: Khi khô hanh gỗ thường co lại và nói chung phần co theo vân ngang lớn hơn phần co theo vân dọc. Tấm gỗ càng mỏng, càng dễ bị vênh. Tấm gỗ dán chính là lợi dụng tính co lại không đều của các tấm mỏng, đem xếp dán các tấm mỏng co theo vân ngang với tấm mỏng co theo vân dọc để tránh nhược điểm trên.

Sở dĩ tấm gỗ dán có số lớp lẻ là để làm cho các tấm gỗ dán có một lớp cốt lõi ở giữa, một mặt khiến các lớp mỏng ở hai phía bị lớp cốt lõi giữ chặt không thể tự do giãn nở, mặt khác cũng làm cho lớp cốt lõi bị các lớp phía ngoài hạn chế. Vì thế tấm gỗ dán bao giờ cũng được dán lớp vân ngang rồi đến lớp vân dọc khác để làm cho các lớp gỗ mỏng kiềm chế lẫn nhau không bị cong vênh hoặc nứt gãy.

CÁC BỀ MẶT GỖ CÔNG NGHIỆP THƯỜNG GẶP LÀ GÌ?

BỀ MẶT GỖ CÔNG NGHIỆP VYNIL LÀ GÌ?

Một loại bề mặt nhựa tổng hợp đặc biệt được nhập khẩu từ Hàn Quốc với kết cấu bao gồm PVC và lớp bao phủ có độ dày theo tiêu chuẩn: 0,12mm / 0,18mm / 0,2 mm. Bề mặt Vinyl được sử dụng để kết hợp cùng Laminate và trên thị trường hiện nay chỉ có nội thất Fami là sử dụng nhiều chất liệu này.

Xem thêm: Thiết kế nội thất chung cư goldmark city 70m2 200 triệu

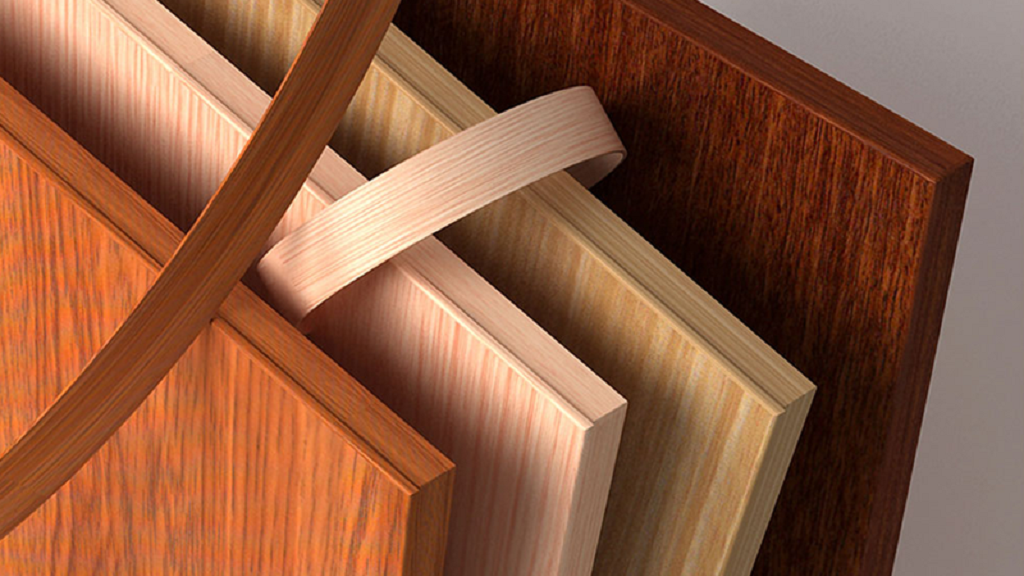

BỀ MẶT GỖ CÔNG NGHIỆP VENEER LÀ GÌ?

Veneer là gỗ tự nhiên sau khi khai thác, được cắt (bóc ly tâm) thành những lát dầy từ 0.3mm > 0.6mm. Rộng tuỳ theo loại gỗ trung bình khoản 180mm, dài khoảng 240mm, được gọi là veneer được phơi và sấy khô.

- Dùng một lớp ván thường là MDF, ván ép, hoặc okal dầy 3mm, tráng keo trên bề mặt lớp nền.

- Nối (may) từng tấm Veneer lại theo quy cách (quy cách chuẩn 1200 x 2400mm) bằng keo-> dán tấm veneer lên lớp nền (MDF, Ván ép) đã phủ keo.

- Ép tấm này lại bằng máy (ép nguội hoặc ép nóng) đến khi dính và phẳng mặt.

- Dùng máy chà nhám tạo cho bề mặt veneer láng đẹp

BỀ MẶT GỖ CÔNG NGHIỆP MALEMINE LÀ GÌ?

Là bề mặt nhựa tổng hợp, Melamine có độ dày rất mỏng ước chừng 0.4 – 1 zem (1zem= 0,1mm), được phủ lên cốt gỗ, thông thường là cốt gỗ Ván dăm (Okal) hoặc Ván mịn (MDF). Sau khi hoàn thiện các tấm gỗ Melamine có độ dày thông thường là 18mm và 25mm. Các tấm gỗ phủ Melamine – MFC có các kích thước phổ thông là 1220 x 2440 hoặc 1830 x 2440mm.

BỀ MẶT GỖ CÔNG NGHIỆP LAMINATE LÀ GÌ?

Bề mặt Laminate là bề mặt nhựa tổng hợp tương tự như Melamine, nhưng dày hơn Melamine nhiều. Độ dày của laminate là 0.5-1mm tùy từng loại ( có thể phần biệt laminate và Melamine qua độ dày), tuy nhiên laminate thông thường vẫn sử dụng có độ dày là 0.7 hoặc 0.8mm. Cũng như MFC, Laminate chủ yếu được phủ lên các cốt gỗ Ván dán (Okal), Ván mịn (MDF). Ngoài ra Laminate còn có thể dán vào gỗ uốn cong theo công nghệ postforming, tạo nên những đường cong mềm mại duyên dáng. Lớp bề mặt Laminate của Fami có độ dày tiêu chuẩn là 0.75mm, có tên gọi kỹ thuật theo công nghệ Hàn Quốc là Melamine HPL (HPL: High Pressure Laminates).

Với những kiến thức trên đây mà chúng tôi cung cấp, chắc các bạn đã hiểu rõ gỗ công nghiệp là gì rồi nhỉ. Bên cạnh đó, bạn còn có thêm nhiều thông tin về các loại gỗ công nghiệp và những bề mặt gỗ phổ biến. Qua đó, bạn có thể lựa cọn loại gỗ công nghiệp phù hợp nhất cho những đồ nội thất của nhà mình.

Nếu bạn muốn hoàn thiện nội thất nhà mình với

vật liệu

gỗ công nghiệp thì hãy liên hệ ngay với:

CÔNG TY

XÂY DỰNG

MV – MỜI VÀO NHÀ TÔI

Hotline: 0908.66.88.10 – 09.0202.5707

Địa chỉ: 201 Bà Triệu, quận Hai Bà Trưng, Hà Nội

Email: gdmoivaonhatoi@gmail.com

Website:

https://moivaonhatoi.com/

Fanpage:

https://www.facebook.com/Thietkethicongnoithat.moivaonhatoi/